MANUFACTURING TECHNIQUES

From prototypes to series production.

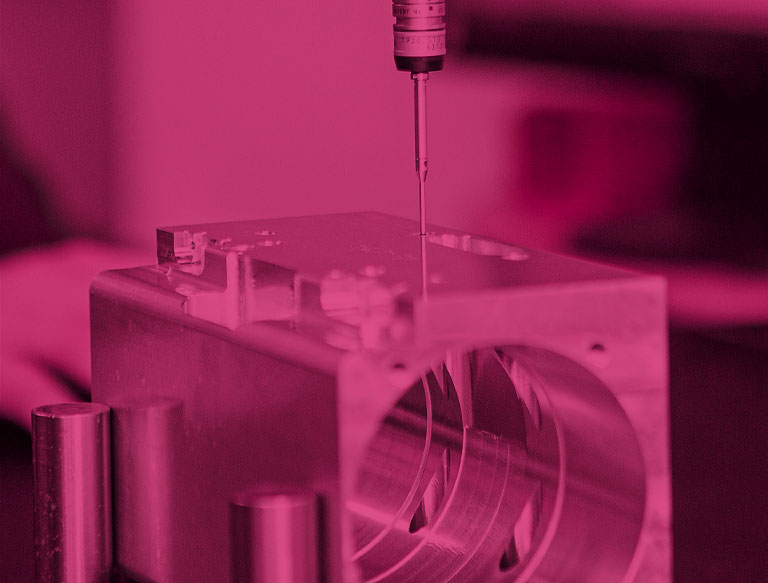

In our processing centres we can manufacture high precision and high quality components which meet your most stringent requirements.

With the aid of precise 3D measurement technology and the latest CNC machines we manufacture manually executed precision parts tailored to your needs.