DE

MENU

MENU

EGGERS CNC will present itself at two trade fairs in 2023. Take the opportunity and get to know us personally on site.

We are looking forward to your visit.

Industry is considered to be one of the biggest energy sinners - we want to do better! That is why we have equipped our production facility with a photovoltaic system of over 800m2.

On average, 20% of our electricity needs should go into the battery storage, 40% should be consumed directly and another 40% should be fed into the grid (mainly in summer). We will then retrieve this fed-in electricity from the grid during the winter months. The system will produce an average of 117,736 kWh per year.

If the electricity we generate is ever insufficient, we will purchase electricity from renewable sources so that we can still remain climate neutral.

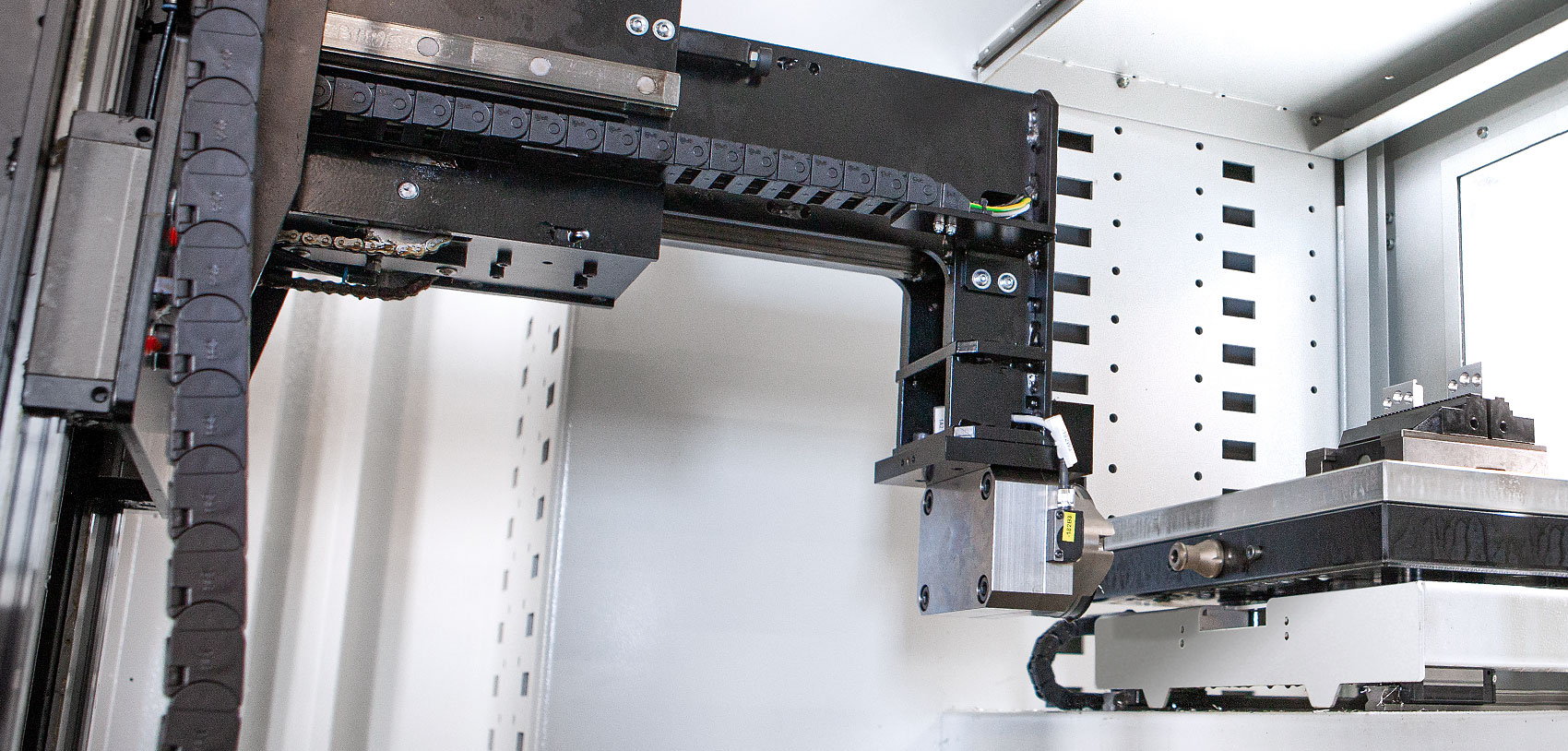

On the way to Industry 4.0 “Innovation through investment” we have since 2019 focused on automation technology, as a first step with 5-axis simultaneous machining, to achieve even greater efficiency in production.

The manufacturing process with a fully automated manufacturing cell does not only offer economic benefits to our customers in machine, vehicle and plant engineering.

Automated manufacture reduces environmental influences on the production process, which increases the quality and safety of the process.

We produce spare parts for all types of ice-cream cone maker. We can ensure the cost-effective and high quality production of any spare part which requires mechanical processing.

We can completely refurbish your ice-cream cone maker – from the removal heads through the rolling mould and the rolling core to the complete baking chain.

We also offer used ice-cream cone machines, which can be modified specially for customers. On request, we can equip your machines with our stainless steel rolling moulds.